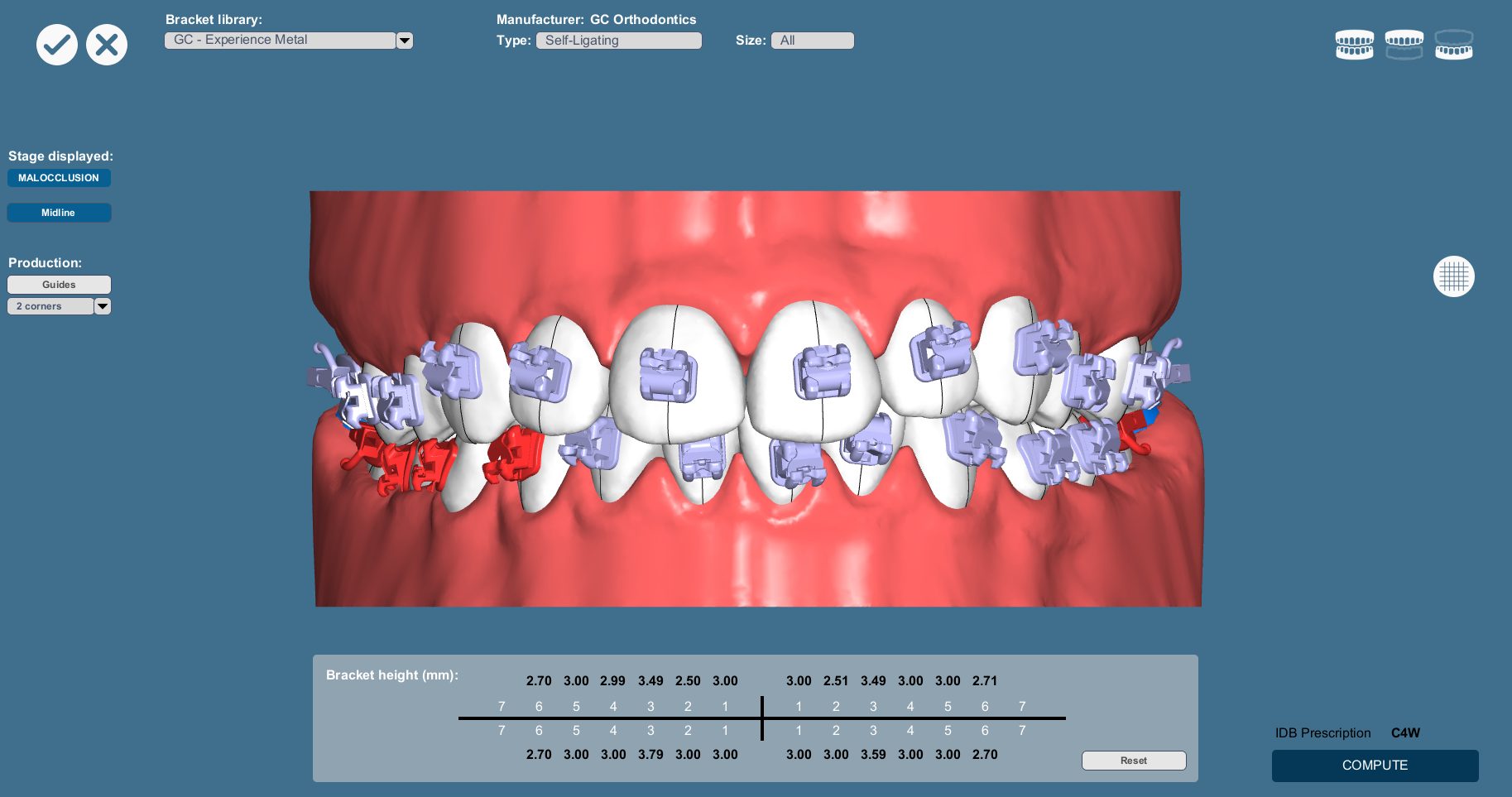

ORTH’UP IDB integrates advanced bracket placement with a simple workflow based on the initial model, without any teeth displacement. The operator efficiently displays both arches models, defines brackets position parameters, and visualizes model result.

ORTH’UP also allows you to export your 3D models to create indirect bonding trays, improving productivity and efficiency in modeling.

Advanced placement of brackets

ORTH’UP Indirect Bonding (IDB) lets you select your bracket library and position them thanks to powerful calculation on the scanned model – either on the current malocclusion or after a setup. Furthermore, you can easily add a prescription to best suit your daily practice. The entire process takes only 10 minutes.

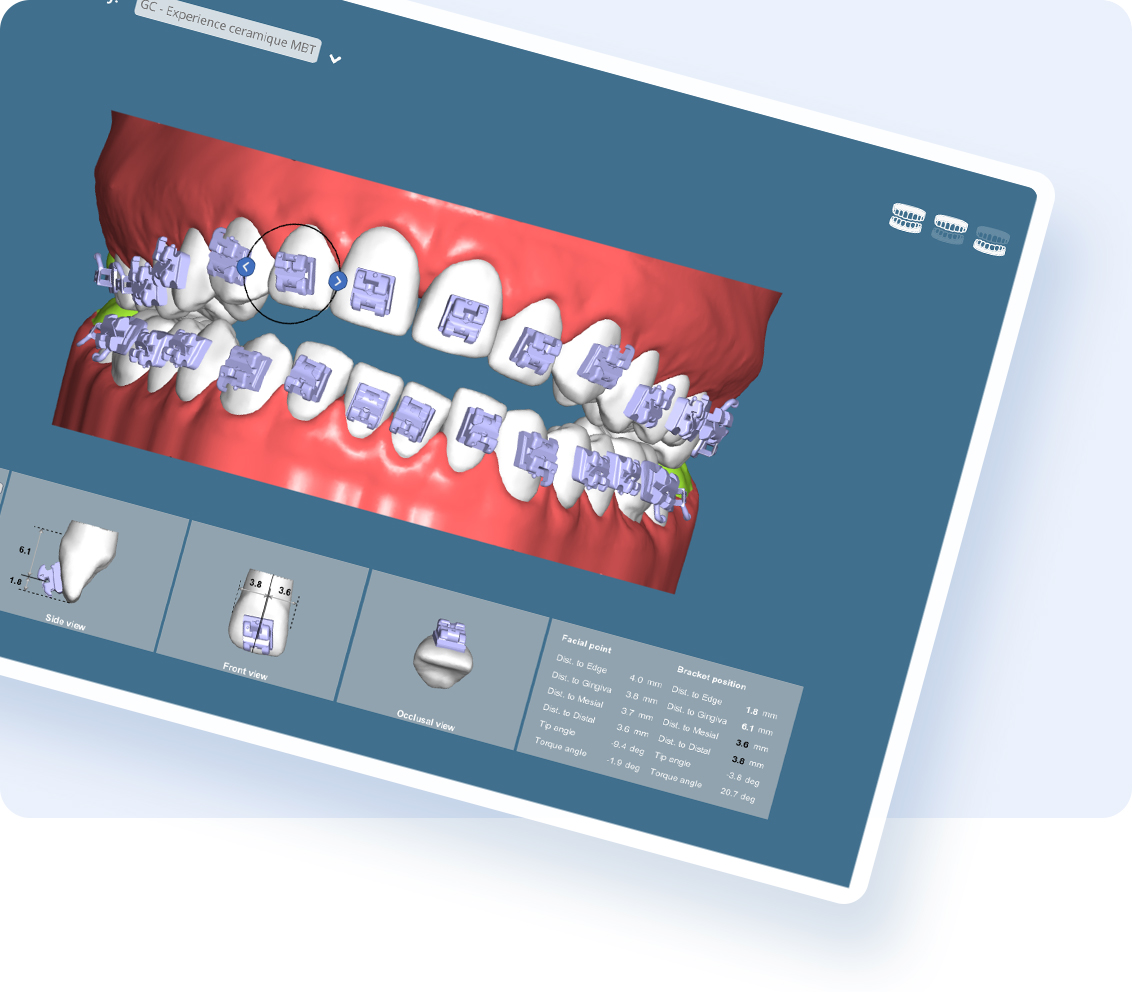

Precision technology

ORTH’UP IDB calculates the precise degree of tip and toque, as well as the distance to the edge and gum and mesial and distal. Thanks to these advanced calculations, tooth movements become remarkably predictable. Brackets are then placed with rigor and accuracy thanks to powerful computation, based on the bracket library, and the given prescription.

Create your transfert trays in 3D

ORTH’UP IDB brings you the best-of-breed innovative CAD technologies and gives you the possibility to manufacture your trays. A custom 3D-printed transfer tray is designed to hold the brackets according to their placement. Compatible with most 3D printers, it has never been so easy to print the 3D tray and to freely transfer all brackets in one step to the teeth.

Add some guides to your models

You prefer not to print the transfer tray directly? That’s not a problem. ORTH’UP IDB allows you to add guides to your 3D-printed models. You can choose from different options such as bars, corners, U-guides, etc. Then, you simply glue your brackets onto the models using the guides before thermoforming a transfer tray.